Moser Energy Systems Emissions Catalysts

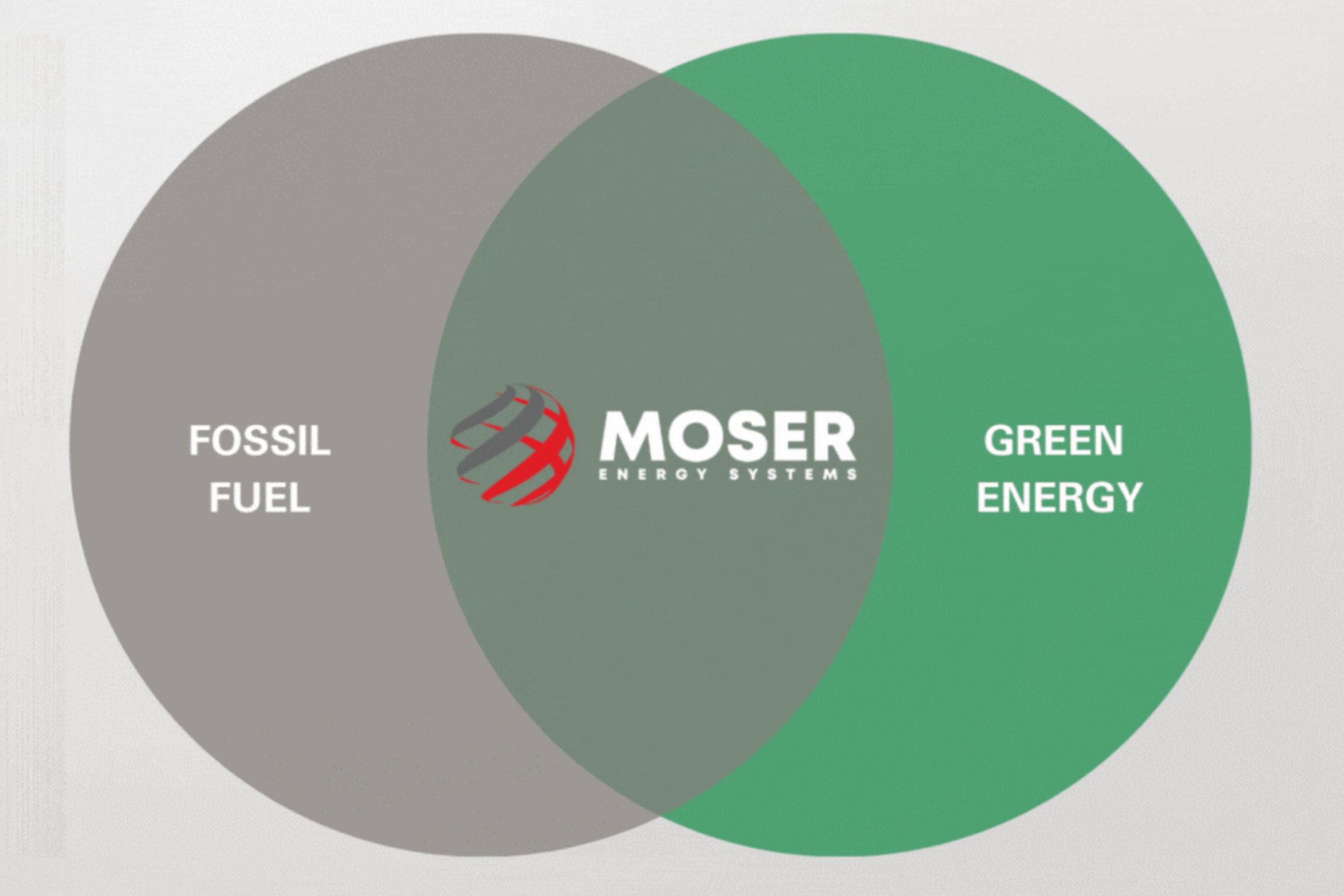

At Moser Energy Systems, one of our biggest strategic goals is to differentiate ourselves from others when it comes to generator services, particularly in the oil and gas industry. Moreover, we want to create clean energy systems that are, in fact, even cleaner than power grids.